ISOLCOMER

Renovation system

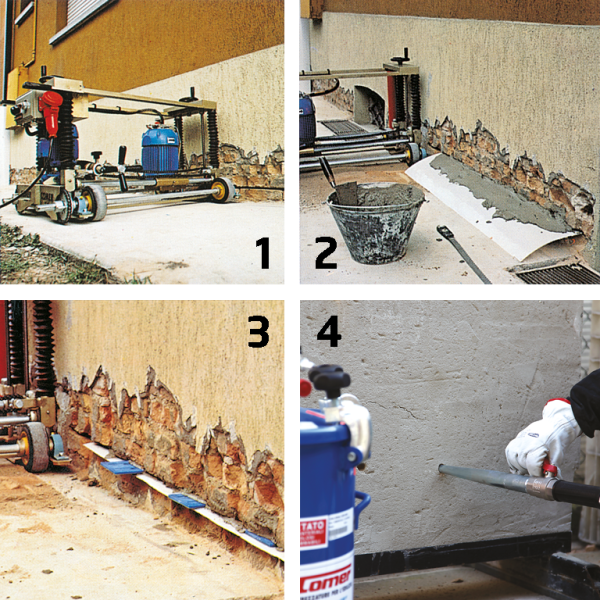

1 - FIRST STAGE

Cutting

The first phase of the procedure consists in cutting the wall subject to the rising humidity phenomenon with special machines built by COMER, EDIL T. The characteristic of these machines is the possibility to adjust the cut both in height and in inclination and depth. Cuts of very high thicknesses are also possible, and non-repassant cuts can be made if coatings already installed on one side of the wall are to be safeguarded. The cut is necessary on the load-bearing walls, perimeter and interior that rise directly from the foundation, since from these the humidity rises by principle of capillarity.

Cleaning and washing

In this phase, the cutting section is cleaned and washed to facilitate the insertion of the ISOLCOMER sheath and the subsequent filling with cement mortar.

2 - SECOND STAGE

Insertion of the ISOLCOMER sheath

Is the most important phase of the process and consists in inserting in the cut performed in the wall, a sheet of insulating sheath ISOLCOMER that prevents moisture from rising, creating a barrier against rising moisture. The sheaths can be made of smooth and bi-sandblasted fiberglass. The latter allows an excellent adhesion of the injected mortar.

3 - THIRD STAGE

Zepping

Very important at this point is the pressure insertion of the plastic anchor wedges. Comer wedges are equipped with holes with insertion channel for the mortar and have the triple function to compress and permanently block the insulating sheet in the cut and to give temporary stability to the masonry waiting for filling and subsequent drying of mortar. The insertion of wedges takes place by pressure with the help of the special "wedge beater".

4 - FOURTH STAGE

Filling with additive cement mortar

It consists in the saturation of the cut with cement mortar additive of expansives and antiritiri and its subsequent insertion in the masonry. For this process the mortar can be inserted with tanks of different sizes AIRJET COMER for the forced injection of mortar.